Harnessing the Power of Synthetic Biology and 3D Printing: Introducing Programmable Living Materials

The Potential of Programmable Living Materials

In recent years, scientists have embarked on a groundbreaking journey to create a new class of materials that possess the remarkable ability to grow, repair themselves, and respond to environmental stimuli. These revolutionary materials, known as engineered living materials (ELMs), are crafted by embedding living cells within an inert matrix, allowing them to thrive and function in various applications. Among the most promising developments in this field is the marriage of synthetic biology and 3D printing, which has led to the creation of programmable living materials with unprecedented capabilities.

Exploring the Evolution of Engineered Living Materials

Engineered living materials have emerged as a cutting-edge area of research, with scientists harnessing the potential of living cells to generate novel materials with unique properties. While early efforts primarily relied on bacterial and fungal cells as the living component, recent advancements have sparked interest in utilizing plant cells to create engineered plant living materials (EPLMs). However, previous attempts to develop plant cell-based materials have been limited by their simplistic structures and functionalities.

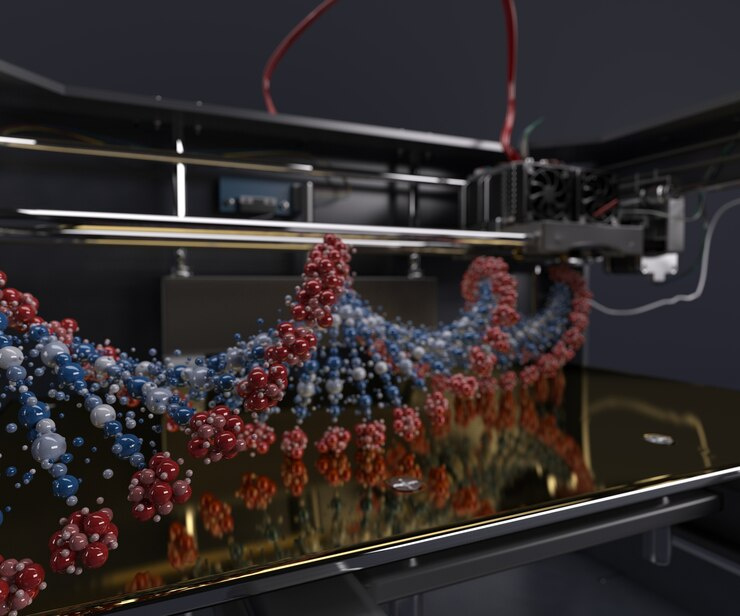

Breaking New Ground: 3D Printing Bio ink with Genetically Modified Plant Cells

In a groundbreaking study published in ACS Central Science, researchers have achieved a significant milestone by successfully 3D printing bio ink containing genetically modified plant cells. Led by Ziyi Yu, Zhengao Di, and their colleagues, the team aimed to create intricately shaped EPLMs with customizable behaviors and capabilities. By mixing tobacco plant cells with gelatin and hydrogel microparticles containing Agrobacterium tumefaciens, a bacterium commonly used for DNA transfer in plants, the researchers developed a bio ink capable of producing programmable materials.

Shaping the Future: Complex Structures and Multifunctional Capabilities

Using their innovative bioink, the researchers demonstrated the ability to 3D print a diverse range of shapes, including grids, snowflakes, leaves, and spirals. After curing the printed materials with blue light to harden the structures, the team observed the transfer of DNA from the bacteria to the growing tobacco cells over the following 48 hours. As the plant cells replicated and grew within the EPLMs, they began producing proteins dictated by the transferred DNA.

Unlocking Potential Applications: From Biomanufacturing to Sustainable Construction

The implications of this research are far-reaching, with potential applications spanning biomanufacturing, sustainable construction, and beyond. By harnessing the unique properties of EPLMs, scientists envision a future where these materials serve as cellular factories for producing plant metabolites, pharmaceutical proteins, and other valuable compounds. Additionally, EPLMs could find use in sustainable construction applications, offering a biodegradable and environmentally friendly alternative to traditional building materials.

Conclusion: Paving the Way for a Sustainable Future with Programmable Living Materials

In conclusion, the marriage of synthetic biology and 3D printing has unlocked new possibilities in the realm of materials science, leading to the development of programmable living materials with unparalleled capabilities. As researchers continue to push the boundaries of innovation, the potential applications of EPLMs are poised to revolutionize various industries and contribute to a more sustainable future for generations to come.

Written By:-